I have wanted to write product reviews for Adventure Unicyclist for some time, after modifying, breaking, and throwing many parts away in frustration. I hope you find my views as a road unicyclist useful. While I try to be impartial…much of unicycling comes to personal preference.

With my latest 36” Triton build, I thought this would be a good chance to look at some recent unicycle parts. I raced this rig at UNICON 16 in the Marathon, 100k, and 10km events, so the equipment was pushed pretty hard.

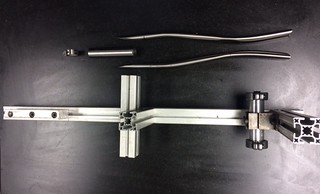

The 36” Triton Frame

I had ridden a standard KH 36” for about 4yrs. While it’s not a bad frame, there are several shortcomings, specific to aluminium rather than the KH. Namely, the frame looks fine for a few rides, but after numerous dings, crashes and corrosion, it looks terrible. Aluminium is comparably soft- I’ve stripped the thread on an old KH frame and several (non-KH) aluminium cranks.

Not so with the titanium. It costs more, but what you get is virtually bombproof and will look like it came out of the factory many years later. Recently, my 2008 Triton 29” was scratched to bits against spikey pedals. With steel wool, it polished up nicely and you can’t tell it apart from a new one. If you want something cheap, light and stiff, and blue is your favourite colour, you can’t go past the KH frames. They work for most people, and they are constantly being updated. In terms of value for money- that is a difficult proposition…although the Triton costs more than twice the KH, it will last much longer.

The 36” Triton disc is similar to the previous Tritons, but comes complete with disc tabs for a 180mm rotor. This was built to take the original SINZ Mt Uni Disc Brake cranks, but it is also compatible with the KH Spirit Disc brake. Magura brake bosses are included if you wish to run rim brakes. An added bonus of having disc tabs is that you can use different wheelsets on the same 36” frame.

For someone short like me, it helps that the seatpost has been cut low. The frame is available in brushed bare metal titanium with big industrial ‘TRITON’ stickers down each fork leg. You’re given a spare set of stickers, but they do come off after hard use, so I leave them off after. The welds are clean and functional, almost on par with my $8000 Litespeed Archon road bike. The fork legs are low in profile to avoid rubbing your heel, but if you have fat thighs like me, you may still squish them against the fork crown, even though it has been cut off at an angle to minimise this.

The wheelset

The original wheel consisted of a 2008 KH/Schlumpf hub built on a Nimbus Stealth Rim. Unfortunately the spokes were laced in a 4 cross pattern instead of 3 cross (*because there were no spokes of suitable length in NZ the time). As a result, the wheel was as flexible as a noodle, and resulted in significant brake rub. Despite truing and re-tensioning, I had to release the brake completely when doing the Lake Taupo Cycle Challenge last year. Added to my misery was the gorilla like strength required to pry a Nimbus Nightrider tyre off the rim. I’d had enough and decided to rebuild the wheel.

The new wheelset was built with the Nimbus II rim, using the same shaved Nightrider tyre I had previously. I replaced the heavy 36” inner tube with a clear 36” Foss Tube for a weight saving of another few hundred grams. This made for a stiffer, lighter, livelier wheel, but best of all, I no longer dreaded changing my tyre! The bead rolled off the rim easily, only needing gentle coaxing with a tyre lever; rather than the lubricated, grimacing, yelling, hernia popping experience I was used to.

The Disc Brake and Spirit cranks

The disc was a mid-range set of Shimano Deore caliper paired to a Shimano XT 180mm rotor. It was cheap and functional, and the mechanics at my local bike shop are big fans due to their ease of servicing. They had more than adequate stopping power and modulation.

I used a KH Starfighter extension on the brake lever. At NZ$40, it is a pretty expensive lump of not much aluminium, but looks cool and works well. Compared to the earlier KH plastic spooner, it should last longer and is more adjustable (and hence fit more styles of lever). I only wish it looked like the Millennium falcon rather than a wimpy Starfighter….I have to turn the brake towards my lever hand to reach it adequately.

The disc rotor was bolted onto the new KH Spirit dual-hole cranks, in 125/150mm size. I was never a fan of dual-hole cranks- they look crude and inelegant. How wrong was I! The extra fiddlyness of setting up a disc brake, putting on a Schlumpf crank, and getting a torque lever in narrow places; was enough to convert me. I found the 125mm cranks much smoother, but moved back to 150mm for added power. All done with little more than an allen key.

The main concern with disc brakes and Schlumpf hubs are frame clearance issues. On older model KH Aluminium frames, some filing/shaving is required in order to get adequate clearance between the hub and the frame, and between the frame and the rotor bolts. The titanium frame is less chunky than the aluminium KH, but I was still concerned about the amount of clearance I’d have with my rotor bolts. When the disc finally arrived, I was relieved to find about 1- 1.5mm gap between the rotor bolts and the outside of the bearing caps

And then the unexpected happened- or perhaps the expected unexpected. After a few rides with my new setup, the Schlumpf hub broke! A spoke had ripped out of the flange on the hub. I found out later that the older KH/Schlumpf hubs require directional spoke lacing (the spoke holes are not symmetrical) – something my bike shop wasn’t aware of nor was it specified when I bought the original wheel four years ago. My wheel builder had laced the wheel the wrong way, which put too much tension on the flange and ripped a spoke through it.

The 2012 KH Schlumpf hub

Luckily for me, Florian Schlumpf happened to be at UNICON, and I purchased a new hub to install in my unicycle, and Marco Vitale kindly rebuilt the wheel for me. Now, I have a new hub to review as well, which in theory, should work better as it has a longer axle and hence should have greater disc brake clearance.

If only life were so simple. The new hub axle is 4mm longer than the old (152mm vs 148mm), but when I installed the cranks onto the hub, they sat further in on the ISIS splines. Now, instead of 1- 1.5mm clearance, I had zero clearance between the rotor bolts and the bearing caps of the Triton frame! I temporarily solved this issue by putting PVC tape on the spline- which pushed the crank out just enough that I have a few microns separating the rotor bolts (and myself) from oblivion should they ever come loose . I have since shaved the Triton bearing caps with an angle grinder, and I now have about 1mm clearance.

The other clearance issue facing many disc users the gap between the inner fork leg and the Schlumpf dust cap. I believe this is a problem for the newer hubs because of some extra (bulkier) seals. However, it is not a problem on the Triton, which has oodles of inner clearance due to the thin tubing.

The Nimbus Flat seat and handlebars

I have used most editions of the KH Seat since they first came out. Coming from a bicycling background, I cannot see why unicycle seats are shaped like horse saddles. A seat should support your ischial tuberosities (the bony protuberances of your pelvis), and then not wedge against your crotch.

I thought I’d try the Nimbus Flat, which is one of the newer, thinner seats available. When it arrived, I was disappointed at how fat it looked…it was as thick as my regular (shaved down) seats. It was thicker and wider up front than the Impact Naomi- my favourite seat (and the only one where I have not cut down the foam).

The cover is stapled on, rather than relying on shoelaces to hold it together, which makes it difficult, if not unfeasible, to modify. For the aesthetically challenged, the seat cover looks like a pigeon shat on it. The only redeeming factor is that the grey colour matches Titanium.

Comfort wise, it is passable, and definitely better than overstuffed horse saddles like the KH Freeride (although you can easily trim the foam). The wide front and upwards bend does get in the way, but until we get a flat, narrow, thin, seat, this is all you can expect.

At 750g, the weight is comparable to the Impact Naomi and KH Slim saddles, but still three times heavier than an equivalent bicycle saddle. I used a KH T-Bar, which bolts onto the Nimbus saddle nicely. If you run this handlebar setup, get the Nimbus Flat (or other KH style seat). If you don’t use a KH T-Bar, get the Impact Naomi.

How does the whole thing ride?

My 36″ Triton Schlumpf rides pretty well for a geared unicycle. The wheel is stiff and it tracks well. This is partly due to the new wheel build, and partly due to the very rigid Titanium fork legs. I had a few crashes, but the frame handled it all and I haven’t noticed a single scratch or dent.

My favourite thing (despite the complexity) is the disc brake. It is so buttery smooth I found myself using it more than I am accustomed to. No sudden grabs, no disc rub, and strong enough to give me confidence to descend technical downhills in high gear. I think a disc brake is necessary if you are riding a Guni, simply because of the extra speed you have to keep in check.

Shifting was good with the KH Spirit cranks- they flare out but I didn’t notice the extra Q-factor (probably because of the higher gear and lower cadences). They are about 150-200g lighter than the older KH Moment cranks, which I refuse to put on any unicycle because of the weight.

The seat got in the way a little because of the bulk (compared to my cut down seats), but I completed the 100km Unicon race without too much discomfort. .

The newer KH/Schlumpf hub is reinforced at the flange to prevent further breakages, and can now be laced in both directions, so that is a big plus. Aside from the rotor bolt clearance issue (really, the axle needs to be longer), it worked as well as the old hub. I didn’t notice any difference in shifting performance over the 2008 KH/Schlumpf hub. As with all Schlumpf hubs, it’s bloody heavy, and it makes the unicycle feel like a tank, but it’s the sacrifice we have to make for racing.

So in summary- I love the frame, I like the disc, I can put up with the saddle, and the geared hub works as well as you can expect at this stage of development.

(*note that pictures below show a cut down KH Freeride seat, not the Nimbus Flat)